Kent Longridge, Principal Engineer, InterMoor, an Acteon company, answers questions about the various mooring options for floating wind turbines.

Q: WHAT NEEDS TO BE CONSIDERED WHEN DESIGNING THE MOORING SYSTEM FOR A FLOATING TURBINE?

A: Designing a mooring system for a floating energy production system is complex but the overall process is mature. As such, years of past work and project experience in offshore industries show that many factors must be considered. Factors will vary depending on the type of floating system being moored and the geographic region in which it is intended to operate. These include:

- Mooring system design, fabrication, installation, inspection, maintenance and repair requirements and applicable regulatory codes and standards to obtain and maintain regulatory classification

- The floating system’s station-keeping performance requirements to design a mooring system that will facilitate and maximize energy production and power transmission (e.g., cables, umbilicals, etc.)

- The system’s design life and long-term inspection, maintenance and repair requirements and constraints as they affect mooring component selection

- Site-specific metocean environmental conditions and geotechnical properties that the mooring system and its components must withstand and can be anchored in

- Availability, fabricability and maturity of the selected mooring components

- Installation vessel availability, accessibility and capability

- Local staging and mobilization yard accessibility, availability and capability for mooring equipment and offshore operations support

- Logistical requirements and constraints for shipping, importation and the receipt of mooring and installation equipment

With floating wind turbines, there are additional elements to consider. Turbine proximity for example to other turbines must be accounted for, as it affects energy production efficiency. The system’s interaction with other marine users and marine life must be evaluated. Arrays of multiple turbines moored and anchored together can impact marine traffic and local fisheries. Furthermore, since floating wind turbines can be large structures, they can also have an aesthetic impact on surrounding scenery that potentially can cause adverse effects on local economies that rely on tourism. Considering these impacts during planning and design can mitigate potential concerns. And last but not least, it is also the job of the mooring system provider to ensure that the costs fit into the overall economics of the wind farm, such that the project can achieve its economic objective, in terms of the levelised cost of energy (LCOE).

It is also the job of the mooring system provider to ensure that the costs fit into the overall economics of the wind farm, such that the project can achieve its economic objective, in terms of the levelised cost of energy (LCOE).

Q: WHAT TYPES OF MOORING SYSTEMS ARE GENERALLY CONSIDERED?

A: There are two types of mooring systems:

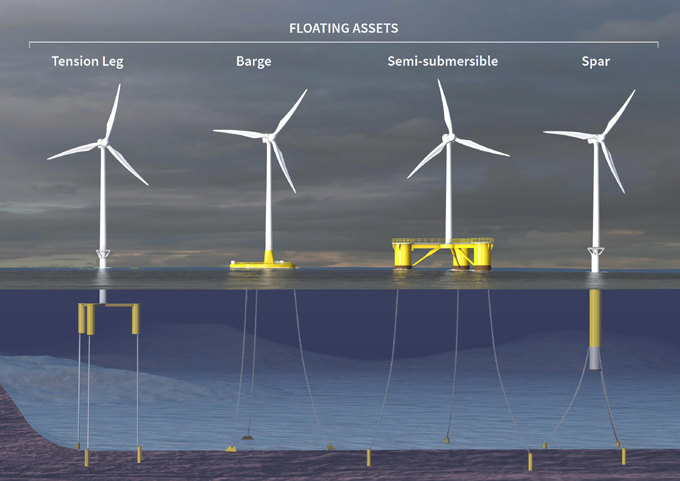

- Tension leg systems are commonly used to moor Tension-Leg Platform (TLP) structures, where they are held in place with vertical tendons that are typically anchored with driven piles that penetrate deeply into the seabed. Deeply driven piles are used to counteract high tension loads in which the vertical component of tension is the largest contributor.

- Spread mooring systems with catenary, semi-taut, or taut lines are often used to moor monohull, semisubmersible, and spar structures. These systems are commonly anchored with drag embedment or suction pile anchors and mooring lines comprised of chain, spiral strand wire, and polyester or other synthetic rope components. Spread moorings are dominated by horizontal tension loads on which they rely to minimize the vessel’s horizontal response to wind, waves and current.

Recent floating wind activity involving a floating spar-like structure will be moored by catenary lines. The Hywind Project in Scotland, which consists of five 6 MW turbines, uses suction anchors and a ballasted catenary layout with three mooring cables and 60-tonne weights hanging from the midpoint of each to provide additional tension.

Q: AS FLOATING WIND PROJECTS DEVELOP, ARE NOVEL SOLUTIONS INVESTIGATED?

A: Yes, novel solutions are also being investigated as the floating wind industry grows. Many concepts and ideas are being pursued to develop different anchoring devices and mooring configurations. Some involve multiple floaters that are moored together (i.e. lines connecting adjacent floaters) and multiple mooring lines anchored with shared anchors.

Other kinds of mooring line components are also being researched, developed and tested. Low stiffness synthetic lines like nylon are being augmented and constructed in ways that make them more fatigue-resistant to accommodate long design lives. Traditional mooring components are being combined in varying ways to achieve composite stiffnesses that achieve preferred station-keeping performance characteristics. Mechanical devices that offer a more compact way of providing design specific stiffness characteristics and load monitoring capability are also being developed.

Regarding installation, new and innovative mooring installation methods and techniques are being evaluated to maximize economies of scale that come with arrays of multiple floaters moored together or near each other. Off-vessel tensioning devices and techniques are also created to minimize the capital expenditure associated with the housing and installation of winches and fairleaders on the floater and to facilitate long-term mooring maintenance and repair work with minimal operational expense. Methods and products that can be installed in shorter amounts of time are also being developed. Saving a short amount of time on a given operation can translate into large savings on commercial wind farms as that operation may take place hundreds of times during a campaign.

With their solid mooring track record including some of the most complex offshore projects in the world, InterMoor and the whole Acteon Group are well placed to apply their extensive domain knowledge to the growing floating offshore wind sector.

This article was originally featured in Energy Global.

KeyFacts Energy Industry Directory Intermoor

KEYFACT Energy

KEYFACT Energy