Aberdeen headquartered maritime technology and consultancy business, Tymor Marine, has launched an innovative new digital technology designed to improve the efficiency, cost and operational impact of performing statutory deadweight audits on commercial and naval vessels.

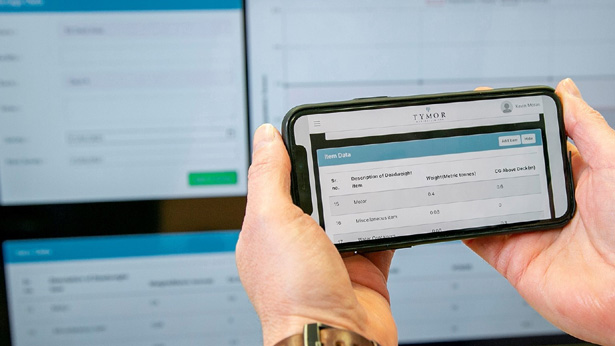

Data log screen displays from Tymor’s new DeadW8.net audit technology

Once installed, Tymor’s new system, called DeadW8.net (DW8), will reduce the cost of future deadweight vessel audits by up to 75%. The greatest benefits will be realised by larger types of vessels, including oil and gas FPSOs, cruise ships or warships that have bigger crews and multiple changes in deadweight that are not always obvious, but the system is applicable to any vessel operator wishing to streamline work, improve efficiency and reduce cost.

Tymor are planning a commercial roll-out of DW8 during 2021 and the company has already received their first order from a leading international offshore drilling contractor. Tymor will also work with their long-standing charitable partner, Mercy Ships, to ensure they are one of the first organisations to benefit on their new build hospital ship, the Global Mercy.

Tymor’s new DW8 technology allows vessel owners and operators to move from a manual, third-party onboard inspection audit, which often interrupts commercial operations, to a secure web-based software system which records and tracks historic information over time.

In addition to reducing the direct costs of the audit, automating the process delivers further efficiency gains. DeadW8 reduces the highly intensive effort normally required from the crew over a short period of time, by embedding the data gathering process into a continuous management system. It also reduces the number of third-party personnel required to collate and verify the information onboard, as well as reducing associated vessel down-time.

The new product draws on a vessel-specific system to capture data and deliver proforma reports to fast-track submission to the authorities. It also builds on a tracked history of prior deadweight information and lightship addition logs to deliver up-to-date details for the vessel’s stability computer and assists in identifying any weight discrepancies. Ultimately, a rich picture is gathered for each vessel, equipping the crew, owners and operators with the knowledge required not only to meet statutory regulations efficiently, but also to improve day to day operational risk and safety.

DeadW8.net can be updated by the crew using a mobile app to scan space related QR codes around the vessel. By scanning a QR code the space is identified, and related information is displayed for verification or update. Objects can be added and removed with visual records, measurements and notes. The system can be tailored for single vessel-based users or allow shore-based users to access multiple vessel databases.

Kevin Moran, managing director at Tymor explained:

“DeadW8.net is a unique resource that will last for the life of the vessel, delivering cumulative intelligence, cost and efficiency savings and enhanced safety. Once installed, the system is completely independent, allowing any crew member, auditor or third-party to utilise it.

“Since the start of the COVID-19 pandemic, we have accelerated investment in R&D to deliver new technology and improve operational efficiencies in the maritime sector. The introduction of DeadW8.net complements our remote auditing service, which was introduced earlier this year. The commercial roll-out of DW8 is now underway. We are delighted to have received our first order from a major drilling contractor and would encourage anyone interested to get in touch.”

Deadweight vessel surveys are normally required every five years, or after major changes, and are performed by a team of auditors conducting onboard inspections. The surveys determine the weight and distribution of a vessel’s variable load, which includes the crew and their effects, temporary equipment, cargo, fuel and water. This allows the lightweight (net structural and fixed weight of the vessel) to be determined by comparing the deadweight calculation with the draught measurement (water displacement). Any change in the lightweight reflects a change in the structure of the vessel which must be approved by the vessel’s own Flag State maritime authority.

KeyFacts Energy Industry Directory: Tymor Marine

KEYFACT Energy

KEYFACT Energy