Living the dream, for many researchers, might include seeing their inventions move from the lab bench to the marketplace. That is certainly an important goal of the funding used to conduct experimental investigations at the National Renewable Energy Laboratory (NREL). While most efforts do not make it to market, the few that do can lead to important changes.

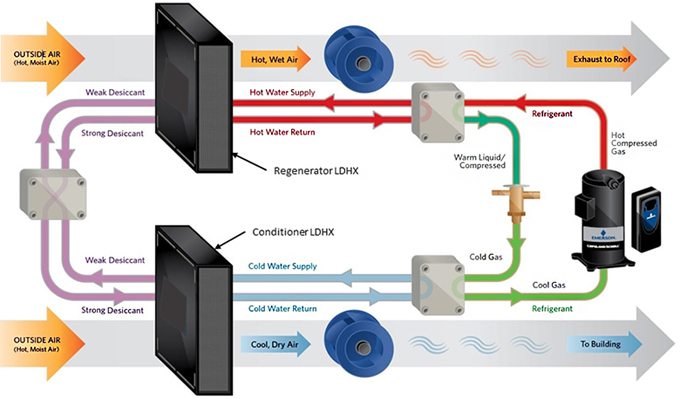

The dedicated outdoor air system developed by 7AC, NREL, and Emerson uses a conditioner powered by chilled water from the refrigeration system and concentrated liquid desiccant solution to provide cool, dry air to a building. The hot condenser water is then used to reconcentrate the desiccant. Recent data show an energy savings of up to 50% when compared to a traditional dedicated outdoor air systems. Diagram courtesy of Emerson

In November 2020, multinational powerhouse Emerson acquired a startup company, 7AC. It was a big deal in the world of cleantech startups - a fairy-tale ending for a startup company whose technology had made it to the HVAC commercial market.

And it was an acquisition celebrated across NREL - by a group of Buildings Program engineers whose R&D advanced the technology and by members of the Innovation, Partnering, and Outreach directorate that managed the agreements, including a grant from the Wells Fargo Innovation Incubator (IN2), that helped launch the HVAC company to commercial success.

7AC founder and Vice President of Technology Peter Luttik described the story as a case study in successful public-private partnerships.

“Working with NREL is a very smart choice for startups and for IN2,” Luttik said. “In our case, we had the combination of a potentially large end-use customer for our technology and, as a technically intensive startup, we needed a lot of expertise. Expertise is what NREL has to offer.”

R&D, Trial & Error

7AC began working with NREL in 2010 when 7Solar founder Peter Vandermeulen came to NREL with a conundrum: They were making solar panels and wanted to know what to do with the solar heat. As Luttik tells the story, 7Solar was looking for a heat sink and thought NREL’s Desiccant Enhanced Evaporative (DEVap) air-conditioning system (a 2012 R&D 100 award winner) might provide that opportunity.

The DEVap technology turned out not to be an exact fit for 7Solar, but it was intriguing, and the company licensed the technology and changed its focus and its name to 7AC. It was a starting point. Then 7AC and NREL launched into several iterations of liquid desiccant heat exchanger technology (LDHX) using a technology services agreement and later a cooperative research and development agreement (CRADA). Eventually, the research took the team from NREL to Anderson Air Force Base on the island of Guam. And the research team expanded to include the U.S. Navy.

By 2016, the team had a 20-ton unit featuring its liquid desiccant heat exchangers in Jubail, Saudi Arabia. While the performance looked very promising, the unit did not last long in the field.

At that point, 7AC and NREL dug in and decided to redesign the heat exchangers, virtually from the ground up. The new design required fundamental engineering and science, in addition to extensive modeling. That is when NREL stepped up with expertise in HVAC design, thermodynamics, heat and mass transfer, and membrane science.

“We built modeling tools and analytical methods that showed how to improve the design of different types of heat exchangers,” explained NREL Senior Engineer Eric Kozubal. “The analytical tools helped with the geometry of the LDHXs, membrane material choices, and balance of system design and control. This eliminated much of the trial and error 7AC had employed in the past.”

The final design: A system utilizing a novel conditioner and regenerator that replace traditional finned-tube heat exchangers. Chilled water from the evaporator and a concentrated liquid desiccant solution power the conditioner to provide cool, dry air to a building. The hot condenser water is used to reconcentrate the desiccant. The system uses a lithium chloride desiccant that can dehumidify down to 15% relative humidity.

And the system can be flexible. In one use case, the LDHXs are used in a dedicated outdoor air system that conditions ventilation air to a building in a variable manner. The system can provide pure dehumidification, dehumidification and cooling, heating and humidification, or cooling and humidification.

Laboratory data from recent pilot-scale systems show that they save up to 50% of the energy required when compared to traditional air conditioning systems, while providing better indoor climate control.

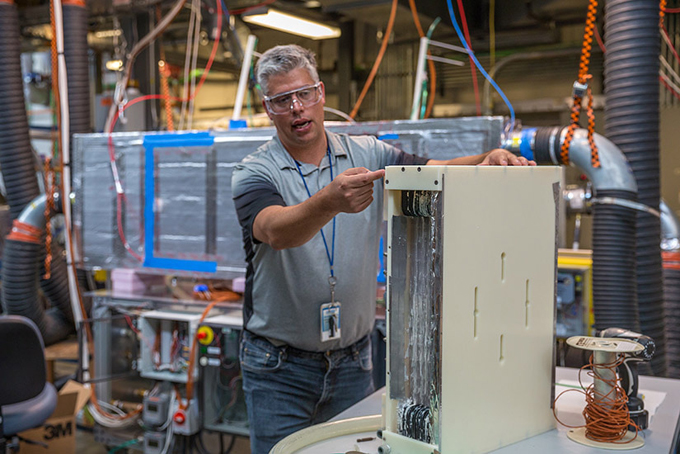

NREL Senior Engineer Eric Kozubal has been working with 7AC and Emerson on the LDHX air system since 2010 and is gratified to see the technology entering the HVAC market.

The Business of HVAC

The work did not go unnoticed. The HVAC market has been interested in separate sensible and latent cooling for years. Existing technology solved this with systems that inherently increased HVAC energy use.

“Before, a typical HVAC system would overcool to wring out the humidity and then reheat,” Kozubal said. “It is not very efficient.”

“3M and Saudi Arabia Basic Industries Corporation (SABIC) were interested in the technology early in our partnership, after seeing a report about the work for the U.S. Navy on Guam,” Luttik said. “Saudi Arabia is very hot with high humidity, and then the wind shifts and it’s very hot with low humidity. The new LDHX system worked under the most difficult environments.”

Then, in 2016, Emerson began looking at the product and invested in 7AC to help move the technology from prototype to market-ready. Additionally, Emerson provided deep manufacturing, materials, and production technology expertise to the LDHX development team. As Luttik explained, this included the same type of technology development processes used to commercialize other Emerson products, like the Copeland compressor. This was critical to move the product from prototyping to commercial production

And all along the way, NREL was engaged in analyses and characterization of the proposed improvements. Through CRADAs and technical service agreements and finally with the help of the IN2 program that provided a $250,000 grant, 7AC and Kozubal’s team at NREL helped the LDHX team understand how each change impacted performance.

“All the analyses at NREL were a strain on the 7AC budget, but we needed NREL. They are objective, and their results are believed,” Luttik said. He explains that IN2 provided an infusion of funding to continue the work at NREL when it was needed most. Kozubal agrees.

“IN2 helped us develop the capability to characterize the heat exchangers in our HVAC laboratory,” Kozubal said. “We were able to evaluate several design iterations in the lab and provided feedback to 7AC’s engineers. Before we knew it, Emerson took notice and got involved. They brought their manufacturing expertise and assisted in the development of production-ready prototypes that were again evaluated in our lab.”

A Win-Win-Win

The win was both professional and personal, for Kozubal. “We helped develop new hardware and gained a lot of knowledge. I’ve been working in this area since 2004, and this is the first product coming out of that research. Desiccant technology is hard to commercialize. There is a long development phase. This is very exciting, and we hope liquid desiccant technology adoption will now accelerate.”

And bonus: The collaboration of NREL with 7AC continues with Emerson.

“We look to a long-lasting relationship with Emerson. We now have several ongoing projects developing energy efficient solutions needed to decarbonize buildings,” Kozubal said.

The impact on the market? Luttik is hopeful that Emerson can scale the technology to the point where it is ubiquitous. “This could do for the AC market, what LEDs did for lighting,” he said.

KeyFacts Energy Industry Directory: NREL

KEYFACT Energy

KEYFACT Energy