By Andy Petrie, Technical Adviser and Andy Kirchin, Managing Director - Technical, Training and Advisory

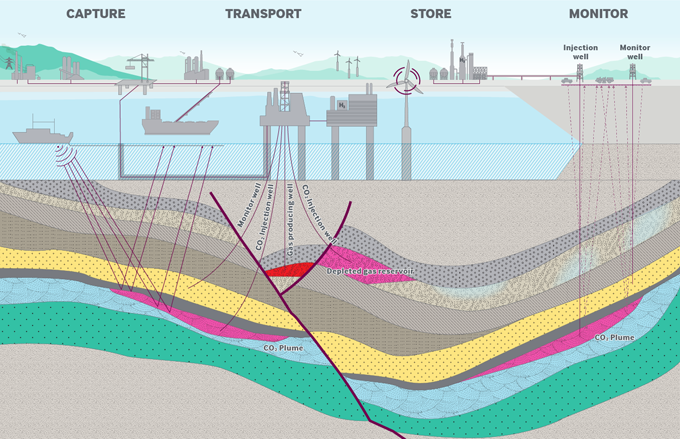

Carbon Capture and Storage (CCS) involves capturing carbon dioxide (CO2) from point source emitters transporting the CO2 and storing it in underground reservoirs, also known as geological sequestration. In CCS projects, the largest source of uncertainty is storage. To manage this uncertainty, there are several factors to consider.

Why store CO2?

Many human activities produce CO2. Increasing our use of renewables for energy will reduce CO2, but sectors such as natural gas power generation, cement manufacturing, steel, chemicals, and agriculture will continue to produce CO2 as an unavoidable part of their industrial processes.

We will need to isolate and remove this anthropogenic CO2 from the earth’s atmosphere permanently to mitigate against global warming and meet net-zero goals.

Where is CO2 stored?

The CO2 is stored in porous rock formations deep below the earth that would otherwise contain water, gas or oil. The storage process is similar to how oil and gas have been trapped underground for millions of years.

Three types of geological storage scenarios (reservoirs) can be considered for CO2 storage. These are saline aquifers, depleted gas fields and depleted oilfields. These reservoirs can be found around the globe.

To evaluate if the reservoir can safely and permanently store the required volume of CO2, we need to understand the physical properties of the reservoir as well as the environmental, health, safety, social and regulatory constraints affecting the asset.

The largest source of uncertainty in any CCS project is storage.

What to consider when storing CO2 in an underground reservoir?

Can we inject CO2 into the reservoir?

Though CO2 is injected into wells like those used for conventional oil and gas, there are additional requirements for storage wells. In the presence of water containing fluids, CO2 forms carbonic acid that can cause severe corrosion to the well completion. Additionally, if a CO2 storage well is not designed, completed and operated correctly, the temperature of the CO2 can rapidly reduce to significantly below zero centigrade as it enters the well. The consequences can adversely affect the well components, such as iron, steel, and elastomers. The ability to effectively manage corrosion and temperature throughout the lifespan of the well is a crucial determinant in well construction and operation.

Does it have the capacity?

Capacity describes the volume of CO2 that a reservoir can contain. Geologists and reservoir engineers working together determine the porous rock volume measured in tonnes of CO2 that the reservoir can hold.

Can the CO2 be contained?

Like gases found in deep reservoirs, CO2 is contained and prevented from entering the atmosphere by the large volumes of rock above the reservoir section. It is important to ensure that neither the reservoir nor the wells leak CO2. Poor well construction or geological faulting can create CO2 leak paths. It is important to ensure the layers of rocks above where the CO2 is stored, the overburden, contain shales or salts, which act as a seal trapping mechanism.

Can it be monitored?

Monitoring the movement of the CO2 after it has been injected is essential to identify any leak paths. A combination of surface monitoring and geophysical techniques, including 4D seismic surveys, is used to identify any safety concerns. Monitoring also establishes the effectiveness of the well and reservoir in accepting the CO2, maps any movement of the CO2 plume, and helps detect any leaks so that corrective action can be taken.

What are the safety risks?

CO2 is a hazardous gas. It is heavier than air and will displace air from contained spaces and, as such, presents a danger to human health and activity. Identifying, understanding and quantifying the safety risks of large-scale projects is critical to ensuring the safe injection and storage of CO2 underground. The most significant risk is CO2 migrating out of the storage reservoir and the physical and chemical effects CO2 may have on the subsurface and groundwater. When identifying a potential storage site, an accurate and complete dynamic model of the reservoir will significantly improve decision making. Safety risks are also addressed during the well design phase. With proper site selection, well design and ongoing monitoring, CO2 storage has proven safe. For example, the Sleipner-West Carbon Capture and Storage facility has been operating safely since 1996.

Deep expertise in underground CO2 storage

RPS has significant technical and commercial experience in underground gas storage, including the geological storage of CO2. Across the CCS lifecycle, we assist and assure clients as diverse as CO2 emitters, CO2 transporters, financial investors, licencing and regulatory authorities, government, and the public. Our teams of geologists, reservoir engineers, compliance and permitting specialists, economists, and ecologists apply their experience to manage the uncertainty related to CO2 storage effectively.

KeyFacts Energy Industry Directory: RPS Energy l KeyFacts Energy News: Energy Transition

KEYFACT Energy

KEYFACT Energy