By Kathryn Porter, Watt-Logic

This week EDF updated its expectations for its nuclear fleet for this winter, downgrading its output forecasts to 275-285 TWh, compared to the previous estimate of 280-300 TWh. The main driver of the downgraded forecasts is a refusal by the French nuclear regulator, Autorité de Sȗreté Nucléaire (“ASN”) to allow EDF to re-start number of reactors with stress corrosion problems, in line with the planned schedule:

- Cattenom 1 (1.3 GW) will be offline for a further three and a half months until 26 February 2023

- Chooz 1 (1.5 GW) will remain closed for about three months until 29 January 2023

- Penly 2 (1.33 GW) will be delayed by more than two months until 29 January 2023

- Cattenom 3 (1.3 GW) will be closed for a further two and a half months until 26 February 2023

- A couple of other reactors are likely to have minor delays to their re-start schedules.

A detailed report has been issued by ASN in relation to the stress corrosion issues at Cattenom 1, where the regulator has instructed that some welds in the affected part of the reactor must be repaired before it can be re-started. Other welds have been authorised to be left until the next scheduled outage in 2023 when EDF intends to replace all of the pipe sections in the safety injection system that are susceptible to stress corrosion cracking.

“During its treatment of the stress corrosion (SC) phenomenon affecting several of its reactors, and in accordance with the strategy it had proposed, EDF carried out inspections on the piping of the Cattenom NPP reactor 1 safety injection system. These inspections, which were carried out close to the welds liable to be the most severely affected, revealed indications that could be attributed to SC cracking. Two of them were of significant dimensions, with maximum depths of 4.7 and 6.1 mm….In the light of the uncertainties surrounding the defect characterisation measurements and the hypotheses and methods used in the mechanical calculations, ASN considers that the strength of the pipes affected by these two indications cannot be guaranteed. The welds concerned will therefore have to be repaired before the reactor can be restarted,”

– Autorité de Sȗreté Nucléaire

The stress corrosion issues were first identified at Civaux 1 during the 10-year inspection last October when faults were detected close to welds on the safety injection-system circuit. “Stress corrosion”, which is only detectible through ultrasonic testing, was found in pipes in the backup safety coolant system. The safety coolant injection system allows the plant operator to pump a neutralising agent directly into the nuclear core in an emergency in order to stop the nuclear reaction.

All of EDF’s reactors are Westinghouse-based pressurised water reactors, most of which opened between the late 1970s and early 1990s. Faults were subsequently found at Civaux 2, Chooz 1 and 2, Penly 1, Chinon 3, Cattenom 3, Flamanville 2, and Golfech 1, mostly 1,300-MW and 1,450-MW type reactors (P4 and N4). France’s 900-MW reactors have not been affected. EDF has completed corrosion repairs on six reactors at Tricastin 3, Cattenom 4, Bugey 4, Chinon B3, Civaux 1 and Flamanville 2, with works ongoing at Penly 1, Civaux 2, and Chooz 2.

The stress corrosion problem has been more significant than initially thought with more repair work needed. 15 of France’s 56 reactors have been offline as a result, with a further 11 out for other maintenance. EDF believes a further 16 reactors may have “high sensitivity” to corrosion – it expects the fleet will be fully inspected by 2025. ASN has suggested that weld repairs, deviations from normal weld procedures, and thermal stratification in stagnant lines may have contributed to the cracking.

EDF had completed repair work at Civaux 1, and was carrying out a high-pressure hydraulic test of the primary cooling circuit when steam was released in a room of the reactor building. The reactor was not loaded with nuclear fuel, no one was hurt nor contaminated, and no radioactivity has been detected outside the building, however testing had to be halted. This incident is unrelated to the stress-corrosion cracks but still needs to be assessed.

The inner insulation tube of a pipe used to introduce sensors into the reactor vessel was ejected into a room beneath the reactor during the pressure test because equipment installed specifically for the test phase broke. EDF will send a robot to secure the radioactive tube in a container allowing employees to access the room, close a valve, and assess the damage caused by water that has been flowing into the room and into a special drain. Although the re-start date of 8 January remains unchanged for the time being, EDF says it is “way too early” to say how this will affect the timetable, and ASN requires EDF to submit a report on the incident before it will make any decision on re-starting the reactor.

If the incident was purely due to a failure of test equipment, then the impact may be limited, but if it is found to be a problem with the cooling circuit itself, that would be much more serious, and could have implications for other N4 reactors.

After closing two reactors this year EDF considers life extensions in the UK

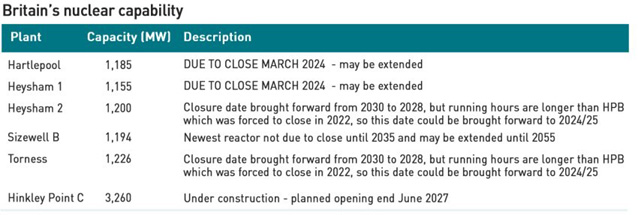

Meanwhile EDF has indicated that it is considering extending the lives of Hartlepool (1,185 MW) and Heysham 1 (1,155 MW) both of which are currently due to close in March 2024. Any decision to extend their lives would need to come soon, before they start managing fuelling towards de-commissioning. Graphite inspections are being carried out which will inform the decision. It is also considering a 20-year extension to Sizewell B which would see it continuing to operate until 2055 – a decision on this is due within the next 18 months.

It is unclear whether its decisions would be influenced by the proposed revenue cap on non-gas generation which would include nuclear. The scheme is apparently under review by the new Prime Minister and may yet be cancelled, but the inclusion of nuclear power is surely questionable. EDF should be incentivised to keep its aging GB fleet open as long as possible, and with further delays to the troubled EPR project at Hinkley Point, and life extensions of the existing reactors should be encouraged. New taxes are unlikely to achieve this.

Further delays and cost over-runs at Hinkley Point C can be expected, and there are still question marks over the future of the planned EPR at Sizewell C. The first of its type reactor in Europe at Olkiluoto is limping towards opening, although the date has now slipped to late December after cracks were found in all of the pumps used to deliver water from the feedwater tank into the steam generators.

The future of nuclear power

In its update on the UK nuclear fleet, EDF says:

“The actual end of generation dates for these four power stations will be determined by the condition of the graphite making up the reactor cores, which is regularly inspected, and subject to rigorous assessment by the independent regulator. Inspections provide reassurance and allow us to meet external regulations. For example, our power stations are required to meet global earthquake regulations – this means we have to prove we can shut down the reactors during a major earthquake, a 1 in 10,000 year event – much larger than the UK has ever experienced or expects to happen.

In light of the severity of the energy crisis and the results of recent graphite inspections, EDF will look to review the case for a short extension for Heysham 1 and Hartlepool to generate beyond the current forecast of March 2024. This will depend on the results of graphite inspections over the coming months. It is important that preparations for defueling continue so that if the stations do end generation in the next 18 months we are operationally ready to start defueling.”

In many ways it’s obvious, but existing reactors, particularly older ones, are unlikely to pass current safety requirements. But it’s reasonable to ask, particularly in light of the difficulties EDF is facing with its EPRs, a problem shared with the Westinghouse AP1000 technology, if current safety standards are too strict. Is it in fact reasonable to require reactors to be able to shut down in a 1 in 10,000 year seismic event of a type never seen in the UK. Why not aim for a 1 in 1,000 year event? What impact would that have on the cost and maintenance of reactors?

“At issue now is our collective ability as a species to recognise and respond rationally to different risks. Do we continue to ratchet up requirements for nuclear energy, which is safe even on a bad day, even with vintage tech, or do we focus on, say, climate change with impacts which are growing in magnitude day by day? …Even nuclear physicists, it seems, can’t agree on the same safety standards for nuclear power plants,”

– David Hess, World Nuclear Association

One of the challenges is to ensure safety standards are appropriate and do not act as a barrier to sensible deployment of nuclear energy.

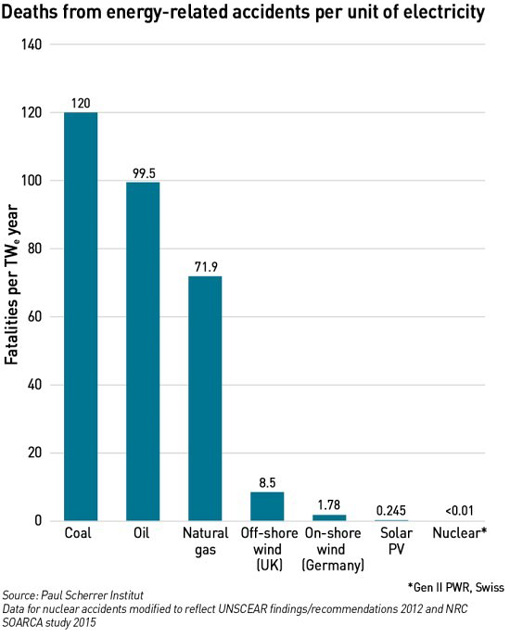

Despite some high profile accidents, nuclear power is extremely safe – there have only been around 30 documented fatalities associated with nuclear accidents (although long-term data relating to Chernobyl are not readily available), and the number of accidents is actually very low: Chernobyl was the most serious, followed by Fukushima, and then Three Mile Island where there was no radiation leak outside the plant.

At Fukushima there were no deaths during the nuclear accident itself and so far, instances of illness and death in people that may have experienced radiation exposure have do not appear to be statistically different from the wider population. By comparison, 19,500 people were killed by the tsunami.

The reality is that all heavy industries carry physical safety risks. The mining industry is particularly dangerous, yet people do not worry about mining safety when buying an electric car for example. The oil and gas industry, particularly off-shore, is also hazardous.

While I agree that all industries should see safety standards improving over time as technology improves and there is a batter understanding of which practices are safe or unsafe, there is a danger that public fears over nuclear safety have led to regulations becoming excessively risk averse to a degree that makes it extremely difficult to deliver compliant new reactors.

Perhaps it is no coincidence that the countries that have seen the largest numbers of new reactors in recent years have been those with a less transparent approach to safety and regulation.

In any case, if countries such as the UK and France are re-committing to nuclear power as a core part of their net zero strategies, the suitability of the safety regimes should be examined to ensure they are fit for purpose and not creating un-necessary barriers. However, it should also be said that companies involved in the nuclear industry need the highest quality control standards, which cannot really be said of EDF following steel quality issues and repeated problems with weld quality.

Nuclear power has no operational carbon dioxide emissions, provides high temperature heat which has many industrial uses, and is not subject to the vagaries of the weather. There is also an opportunity for the UK to re-build its historic nuclear leadership, if it learns the right lessons from the French experience.

Original article l KeyFacts Energy Industry Directory: Watt-Logic

KEYFACT Energy

KEYFACT Energy