By Liz Hartman, Communications Lead for DOE’s Wind Energy Technologies Office

Since the early 2000s, wind turbines have grown in size - in both height and blade lengths - and generate more energy. What’s driving this growth? Let’s take a closer look.

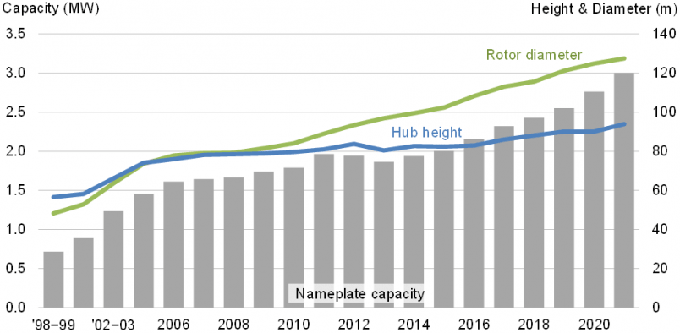

Average turbine hub height, rotor diameter, and nameplate capacity for land-based wind projects from the Land-Based Wind Market Report: 2022 Edition

Hub Height

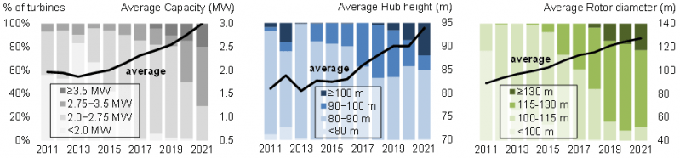

A wind turbine’s hub height is the distance from the ground to the middle of the turbine’s rotor. The hub height for utility-scale land-based wind turbines has increased 66% since 1998–1999, to about 94 meters (308 feet) in 2021. That’s about as tall as the Statue of Liberty! The average hub height for offshore turbines in the United States is projected to grow even taller—from 100 meters (330 feet) in 2016 to about 150 meters (500 feet), or about the height of the Washington Monument, in 2035.

Illustration of increasing turbine heights and blades lengths over time

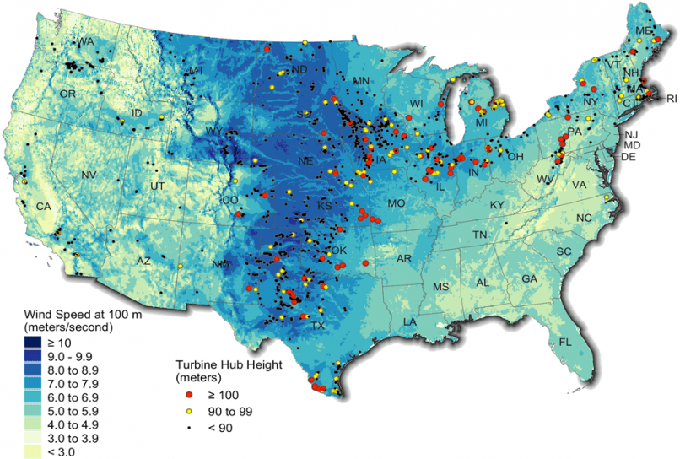

Turbine towers are becoming taller to capture more energy, since winds generally increase as altitudes increase. The change in wind speed with altitude is called wind shear. At higher heights above the ground, wind can flow more freely, with less friction from obstacles on the earth’s surface such as trees and other vegetation, buildings, and mountains. Most wind turbine towers taller than 100 meters tend to be concentrated in the Midwest and Northeast, two regions with higher-than-average wind shear.

Location of tall-tower turbine installations from the Land-Based Wind Market Report: 2022 Edition

Rotor Diameter

A turbine’s rotor diameter, or the width of the circle swept by the rotating blades (the dotted circles in the second illustration), has also grown over the years. Back in 2010, no turbines in the United States employed rotors that were 115 meters (380 feet) in diameter or larger. The average rotor diameter in 2021 was 127.5 meters (418 feet)—longer than a football field.

Larger rotor diameters allow wind turbines to sweep more area, capture more wind, and produce more electricity. A turbine with longer blades will be able to capture more of the available wind than shorter blades—even in areas with relatively less wind. Being able to harvest more wind at lower wind speeds can increase the number of areas available for wind development nationwide. Due to this trend, rotor swept areas have grown around 600% since 1998–1999.

Nameplate Capacity

In addition to getting taller and bigger, wind turbines have also increased in maximum power rating, or capacity, since the early 2000s. The average capacity of newly installed U.S. wind turbines in 2021 was 3.0 megawatts (MW), up 9% since 2020 and 319% since 1998–1999. In 2021, there was an increase for turbines installed in the 2.75–3.5 MW range, while the proportion of turbines at 3.5 MW or larger also increased. Higher capacity turbines mean that fewer turbines are needed to generate the same amount of energy across a wind plant—ultimately leading to lower costs.

Transportation and Installation Challenges

If bigger is better, why aren’t even larger turbines used currently? Although turbine heights and rotor diameters are increasing, there are a few limitations. Transporting and installing large turbine blades for land-based wind is not easy, since they cannot be folded or bent once constructed. This limits the routes trucks can take and the radius of their turns. Turbine tower diameters are also difficult to transport, since they may not fit under bridges or highway overpasses. DOE is addressing these challenges through its research projects. For instance, DOE is designing turbines with more slender and flexible blades that can navigate through curves in roads and rail lines that conventional blades cannot. DOE is also supporting efforts to develop tall turbine towers that can be produced on site, thus eliminating tower transportation issues. Two companies pioneering these efforts are Keystone Power Systems, which uses spiral-welding in order to minimize the need for costly steel, and GE Renewables, which is experimenting with 3D printing to create customizable tower bases.

KEYFACT Energy

KEYFACT Energy