Author: Torsten Marten, Lead Surveyor at UTEC SURVEY

Offshore energy operators are seeking cost effective, accurate and reliable data to support their subsea construction requirements in the renewables and oil and gas sectors. Acteon’s Geo-services construction experts have put together their top considerations to help reduce the cost per survey and increase the overall project efficiency.

EARLY ENGAGEMENT

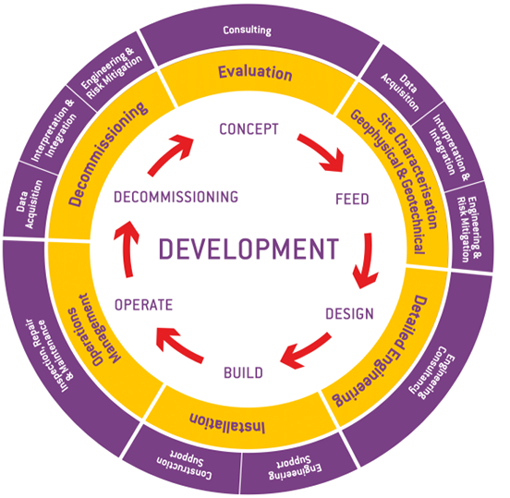

Early engagement with a service provider who has a holistic view of a project lifecycle from site characterisation through to decommissioning enables the operator to plan, mitigate potential challenges, and choose the most optimal foundation design solution.

Aligning the requirements to the tolerances of a project from the outset helps to avoid over-specification, meaning that the service provided can be streamlined whilst still delivering reliable data.

With early engagement, the overall operational schedule can be improved by optimising the individual survey tasks within it.

LEVERAGE THE LATEST TECHNOLOGY AND UNIQUE DESIGNS

Various techniques can be used to reduce project costs such as using different navigation systems. For example, sparse LBL reduces the number of transponders required to cover the field, which reduces equipment costs, deployment time and overall days in the field.

Remote technology can reduce personnel on board (POB) by up to 30% by bringing tasks onshore to reduce travel and aviation costs whilst retaining access to highly skilled personnel when required.

One piece of technology used by Acteon is the comms hub, delivered by UTEC, a geo-services brand in Acteon’s Data and Robotics division. The comms hub provides the communications security and network resilience required to facilitate the delivery of all types of remote services using any available internet connection. This includes remote processing, remote operations, and remote monitoring. The comms hub can provide:

- Live video streams from a remotely operated underwater vehicle (ROV) or any camera on board a vessel to multiple onshore and offshore locations without the need to mobilise any additional equipment or personnel

- Remote access to any computer system on board a ship facilitating remote operations and remote technical support

- Automated file transfer to facilitate remote data processing.

The comms hub enables a reduction in the carbon footprint of operations, as well as costs, whilst retaining access to highly skilled people when required.

Another example of Acteon’s digital technology to reduce environmental impact and mobilisations is iSite, a web-based visual asset management tool that allows clients to remotely access their marine energy assets from their desktops. Using iSite, the user can tour any asset with an intuitive 360° visualisation, undertaking accurate real-world on-screen measurements and view/download all project deliverables, such as point cloud data, drawings, 3D models, photos and reports. In a recent survey, of the users surveyed, 52% recorded significant cost savings, due to reduced offshore working. 48% of the users surveyed, stated they utilise the iSite daily for more effective communication and project planning.

Acteon leverages cross-segment knowledge to design unique systems to increase project efficiencies. For example, on the Wikinger project in the Baltic Sea, UTEC designed a spread of instrumentation to monitor pile installation to the required tolerances. The design was based on having multiple, independent, and calibrated measurement systems that were tested to prove their resilience to the shock loading produced by the pile hammer during piling. This resulted in specialised equipment, software and personnel to support the installation of seventy sets of piles – all to the accuracy needed for turbine installation.

UTILISE A MORE INTELLIGENT APPROACH TO SURVEY

Pioneering a more intelligent approach to survey by replacing traditional monitoring techniques using software and modelling including pipeline touchdown modelling1 eliminates the need for an ROV and vessel. This approach significantly streamlines projects in terms of cost and number of offshore days.

Artificial intelligence (AI) can be used to automate lengthy tasks such as processing and reporting data, reviewing recordings and identifying critical information or events for final human inspection. This provides customers with time-saving benefits and ensures the accuracy of data.

RETAIN KNOWLEDGE THROUGHOUT THE PROJECT

Multi-skilled offshore staff are the key enablers for services to be delivered in a way that reduces carbon emissions, minimises POB and uses remote technology wherever possible. Training staff in multiple disciplines improves quality and continuity of service, allowing the same crew to be involved throughout the whole project to retain knowledge.

Having global reach with localised support means that Acteon has management and technical teams on hand 24 hours a day to provide support and supplier networks where customers need them.

KeyFacts Energy Industry Directory: UTEC

KEYFACT Energy

KEYFACT Energy